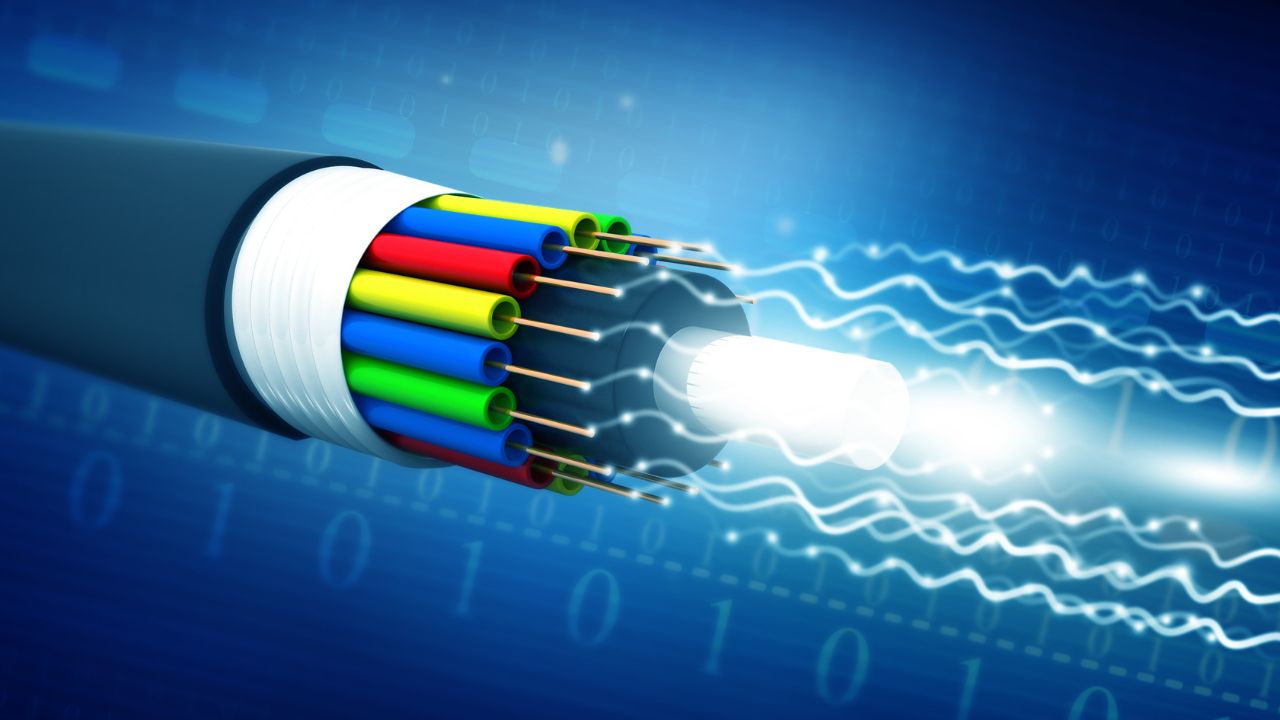

In the epoch of rapid telecommunications and IT development, possessing a powerful and efficient network is crucial, as it was no other day before.

Fiber optic cables represent one of the digits of this dynamic puzzle, boasting unparalleled speed and reliability that make it a vital part of today’s huge digital ecosystem. However, when deciding between the typical and pre-terminated fiber optic cable, IT pros and network designers usually have to ponder over the issue. This article is aimed to overview the most critical points that may help you choose the best pre terminated fiber optic cable for your needs.

Some Points Worth Considering When Opting for A Pre-Terminated Fiber Optic Cable

1. Knowing About Pre-Terminated Fiber Optic Cables

They are fiber optic cables with connectors already installed at the factory and come pre-installed at either end. Now, this prefabrication applies, which reduces the installation time and, on the other hand, brings down the errors that can be made during field termination. The fiber optic families of pre-termination products come in a variety of cable types and connector configurations, tuned to support a bunch of varied applications and networking infrastructure architectures.

2. Determining the Right Fiber Type

It is crucial to select between Single Mode and Multi-Mode fiber optic cables, as they are the two primary types. Single-mode cables are considerably more effective than Multi-Mode fibers for long-distance purposes. They are generally used in contexts where data are to be sent over long distances. However, Multi-Mode cables were specifically designed for shorter distances, meaning within a single building or campus. Hence, the selection will determine your network’s data capacity and distance over which you can transmit signals.

3. Connector Compatibility

The most critical criterion of choice is the type of connectors pre-installed on the fiber. The most common ones are LC, SC, ST, and MTP/MPO connectors. Each of the connectors has its benefits and is compatible with different equipment and patch panels. To integrate pre-terminated fiber seamlessly, the connectors it comes with should fit your network infrastructure or be easily adaptable.

4. Cable Length and Customization

Pre-terminated fiber optic cables come in standard lengths, but one can also order a custom one. In this case, it is important to measure the distance accurately to not get too much slack on one end or expect to have a too short cable. Nevertheless, customization is not restricted to length; the cable’s jacket material, strain relief, or pull tabs may be adapted to the desired installation environment or handling needs.

5. Quality and Performance Testing

Tests on quality pre-terminated fiber optic cables at a factory would ensure the cables’ compliance with average performance characteristics. These would mostly be mechanical strength tests and measurements of the insertion loss. When choosing a pre-terminated type, it is important to ensure that the manufacturer presents the testing specifics for each cable assembly, which will ensure its proper operation.

Conclusion

There are certain points that IT professionals and network planners should consider when they select a pre-terminated fiber optic cable. As these solutions are custom-made products, it is critical to consider the type of cable, its length, and the compatibility of the connectors. In addition, IT professionals should pay attention to customization options, the quality of the pre-terminated cable, and the availability of scenarios when it is more beneficial to order such a product. Opting for pre-terminated fiber optic solutions can streamline installations, enhance performance, and ultimately support the dynamic needs of modern digital infrastructures.